Top Fiber Mesh Tape Manufacturers: Discover High-Quality Options for Your Needs

By:Admin

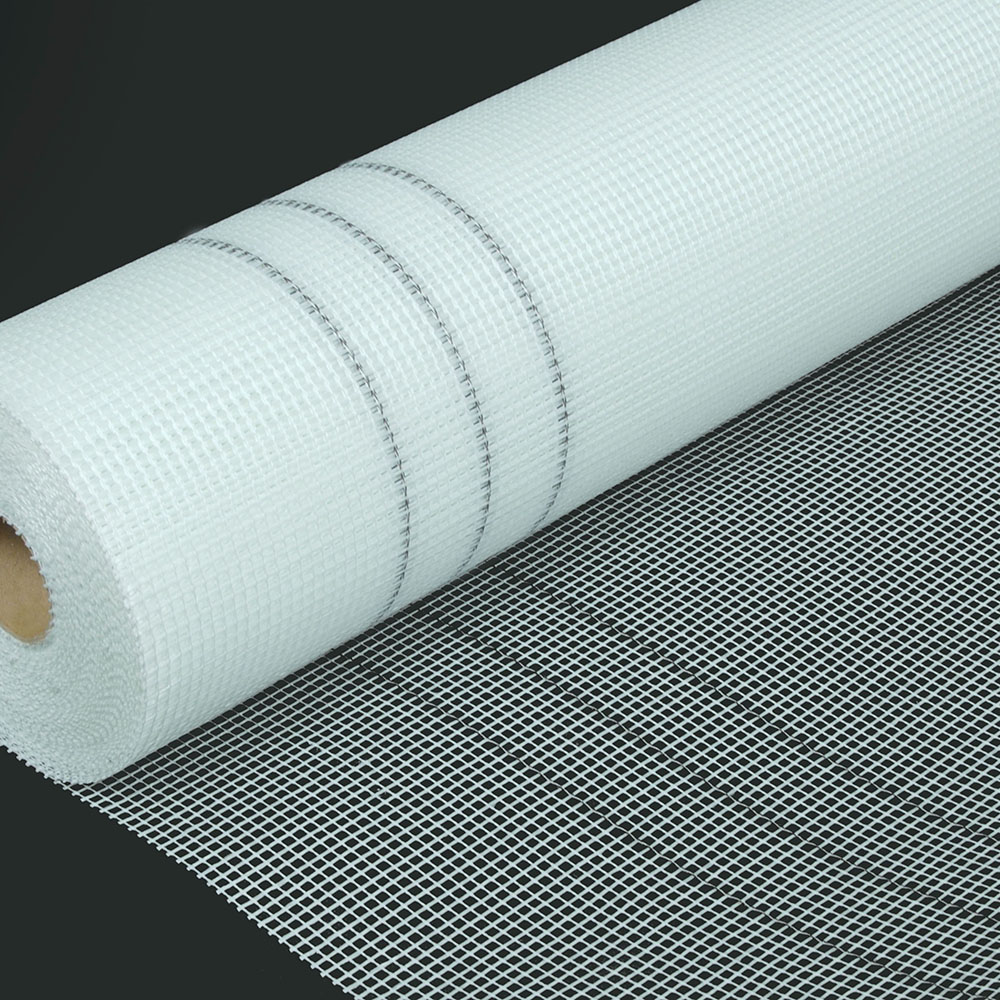

Leading Fiber Mesh Tape Manufacturer Introduces Innovative Product Line for Improved Construction and Renovation Projects

[News Introduction]

[date], [location] - In an effort to meet the growing demands of the construction and renovation industry, a renowned fiber mesh tape manufacturer has unveiled an extensive range of cutting-edge products. With a rich history of delivering effective solutions for builders and contractors, this leading manufacturer aims to enhance the quality and efficiency of both small-scale and large-scale construction projects.

[Company Introduction]

Founded in [year], {Fiber Mesh Tape Manufacturer} has established itself as a trusted name in the construction supply industry. With a state-of-the-art manufacturing facility, the company prides itself on its commitment to research and development, ensuring that its products remain at the forefront of innovation.

Throughout the years, {Fiber Mesh Tape Manufacturer} has continuously pushed the boundaries of what is possible in construction materials. By leveraging the expertise of its dedicated team, the company has developed a range of fiber mesh tapes designed to address the challenges faced by contractors when it comes to durability, quality, and ease of use.

[News Body]

In response to the increasing demand for reliable construction materials, {Fiber Mesh Tape Manufacturer} has introduced a new line of fiber mesh tapes that offers significant advantages for various construction and renovation applications. These innovative products have been carefully engineered to provide builders and contractors with enhanced performance, saving them time and effort while maximizing the durability and longevity of projects.

One of the standout features of {Fiber Mesh Tape Manufacturer}'s fiber mesh tapes is their exceptional adhesive strength. The tapes ensure a secure bond between drywall joints, surfaces, and corners, preventing cracks and minimizing the need for additional repairs. With this advanced adhesive technology, contractors can deliver top-notch finishing and ensure the structural integrity of their construction projects.

Moreover, {Fiber Mesh Tape Manufacturer} has incorporated a superior mesh design into its tapes, which offers enhanced dimensional stability and crack resistance. These tapes are capable of accommodating minor structural movements, reducing the risk of cracks and providing long-lasting performance. Contractors can rely on these tapes to reinforce and strengthen different surfaces, ensuring the integrity of the finished construction or renovation.

Recognizing the challenges faced by professionals in the field, {Fiber Mesh Tape Manufacturer} has also focused on ease of use. The company's fiber mesh tapes feature a user-friendly design, allowing for quick and hassle-free installation. Whether it is a small-scale renovation or a large construction project, contractors can rely on these tapes to streamline the process and improve overall project efficiency.

Additionally, {Fiber Mesh Tape Manufacturer} has taken great strides to prioritize sustainability in its product line. The company's fiber mesh tapes are manufactured using eco-friendly materials, minimizing the environmental impact while providing high-quality solutions. This commitment to sustainability aligns with the global construction industry's growing emphasis on green practices and responsible sourcing.

With the introduction of its cutting-edge fiber mesh tapes, {Fiber Mesh Tape Manufacturer} aims to revolutionize the construction and renovation industry. By delivering innovative products that offer superior adhesive strength, enhanced stability, and ease of use, the company is set to empower contractors, builders, and other professionals involved in construction projects.

Going forward, {Fiber Mesh Tape Manufacturer} remains committed to research and development, consistently seeking new ways to improve construction materials and meet the evolving needs of the industry. With its steadfast dedication to excellence, this leading manufacturer is expected to shape the future of construction and renovation projects worldwide.

[Conclusion]

With its latest line of fiber mesh tapes, {Fiber Mesh Tape Manufacturer} has set a new industry standard, revolutionizing the way construction and renovation projects are completed. By combining advanced adhesive technology, superior mesh design, and eco-friendly materials, the company has positioned itself as a go-to solution provider for professionals in the sector. As the construction industry continues to evolve, {Fiber Mesh Tape Manufacturer} remains at the forefront of innovation, working towards creating a more efficient, sustainable, and durable future for construction projects.

Company News & Blog

Top 5 Benefits of Self-Adhesive Fiberglass Mesh for Home Improvement Projects

Title: Self Adhesive Fiberglass Mesh Factories: Providing Reliable and Efficient Solutions to Construction ProjectsIntroduction:In the fast-paced world of construction, ensuring the structural integrity and longevity of buildings is crucial. Reinforcing materials, such as fiberglass mesh, play a vital role in strengthening surfaces and preventing cracks. Among the prominent players in the industry, Self Adhesive Fiberglass Mesh Factories (brand name removed) have emerged as a leading provider of reliable and efficient solutions to construction projects. With their commitment to cutting-edge technology and superior product quality, they have become a go-to choice for builders and contractors worldwide.Enhancing Structural Stability:Self Adhesive Fiberglass Mesh Factories have been at the forefront of developing innovative fiberglass mesh solutions that significantly enhance the structural stability of buildings. Their products are designed to effectively distribute stress and prevent cracks caused by temperature fluctuations, settling of the building, and other external factors. By using self-adhesive fiberglass mesh, the risk of structural damage is minimized, resulting in long-lasting and durable structures.Superior Product Quality:One of the factors that distinguish Self Adhesive Fiberglass Mesh Factories from their competitors is their unwavering commitment to product quality. Through rigorous testing procedures and quality control measures, they ensure that each roll of fiberglass mesh meets the highest industry standards. The mesh is made from high-quality materials and undergoes strict inspection to guarantee its strength, adhesive properties, and resistance to environmental factors. Builders can have peace of mind knowing that the self-adhesive fiberglass mesh from these factories will provide reliable reinforcement for their construction projects.Cutting-edge Technology:Self Adhesive Fiberglass Mesh Factories have consistently invested in state-of-the-art technology to stay at the forefront of the industry. By leveraging modern manufacturing techniques, they have increased the production efficiency and precision of their products. Automated machinery ensures consistent product quality, while minimizing human error. The factories constantly innovate and adapt their manufacturing processes to incorporate the latest advancements, staying ahead of the curve in an ever-evolving industry.Environmental Responsibility:Another significant aspect of Self Adhesive Fiberglass Mesh Factories' operations is their commitment to environmental responsibility. They prioritize the use of eco-friendly materials and manufacturing processes that minimize waste and energy consumption. By actively reducing their carbon footprint, these factories contribute to a more sustainable construction industry. Builders who choose their products can be confident that they are making an environmentally conscious choice without compromising on quality or performance.Global Reach:With a vast client base, Self Adhesive Fiberglass Mesh Factories serve construction projects across the globe. Through strategic partnerships and distribution networks, their products are readily available and accessible in various regions. By providing reliable solutions to builders worldwide, these factories have earned a reputation for their exceptional customer service and commitment to fulfilling project requirements.Future Innovations:As the construction industry continues to evolve, Self Adhesive Fiberglass Mesh Factories are committed to staying ahead of the curve. They have dedicated research and development teams working on innovative solutions that address emerging challenges in the sector. By foreseeing future requirements, these factories are not only meeting the current demands of the industry but also preparing for the construction needs of tomorrow.Conclusion:Self Adhesive Fiberglass Mesh Factories have emerged as industry leaders, providing reliable and efficient solutions to construction projects around the world. With their emphasis on superior product quality, cutting-edge technology, environmental responsibility, and global reach, they have gained the trust of builders and contractors alike. As they continue to innovate and adapt to evolving industry demands, Self Adhesive Fiberglass Mesh Factories are set to play a vital role in enhancing the structural stability and longevity of buildings for years to come.

Understanding the Functionalities of Fiberglass Mesh: A Guide

for Construction, Fiberglass Mesh Tape, Fiberglass Mesh Filters, and PVC Coating.When it comes to construction, it's crucial to use high-quality materials. From flooring to walls, every element needs to be solid and efficient. That's why woven fiberglass mesh for construction is an excellent option. Fiberglass mesh is an incredibly durable and versatile material that can be used in a range of applications, including tape, filters, and reinforcement. Let's explore how and why fiberglass mesh should be considered in your next construction project.Fiberglass Mesh for Construction Woven fiberglass mesh is strong and lightweight, making it an ideal alternative to traditional materials such as metal. This type of mesh has a crisscross pattern of fiberglass thread that creates a tightly woven fabric. It's incredibly resilient and resistant to damage from ultraviolet light and harsh weather conditions. Fiberglass mesh is also resistant to corrosion, chemicals, and fire, which makes it a popular choice in construction.One of the most common uses of fiberglass mesh in construction is as a reinforcing material. When added to concrete, it can improve the concrete's tensile strength and provide extra support. This is especially important in areas where the application may be prone to cracking.Another use for fiberglass mesh is in flooring. It's an excellent way to reinforce both concrete and wood floors. It can prevent damage from high-traffic areas, improve the load-bearing capacity of a floor, and keep it stable for years to come.Fiberglass Mesh Tape Fiberglass mesh tape is another popular use for the material. It's an adhesive tape that's reinforced with fiberglass mesh, making it incredibly strong and durable. It's commonly used in drywall installation and prevents cracks from forming along seams and joints. Fiberglass mesh tape is also resistant to moisture, which prevents damage from water and other liquids.Fiberglass Mesh Filters Fiberglass mesh is also commonly used in filters. When used in filtration systems, fiberglass mesh has a tightly woven pattern that prevents debris and particles from getting through. Manufacturers often spray PVC coating on the mesh to make it stronger and last longer. These filters are used in a variety of applications, from industrial machinery to HVAC systems.PVC Coating PVC coating is a process where a layer of plastic is applied to the surface of fiberglass mesh. The coating is applied to increase the strength and durability of the mesh, making it resistant to damage from harsh weather and chemicals. It's often used in outdoor applications, such as fencing and agricultural structures.Final thoughts Fiberglass mesh is a versatile and durable material that has a wide range of applications in construction and beyond. Whether you need a reinforcing material, tape, or a filter, fiberglass mesh is an excellent choice. Its strength and resilience make it an ideal alternative to traditional materials, and it can offer decades of reliable use. Don't hesitate to consider woven fiberglass mesh for your next construction project.

Fiberglass Cloth Tape, 6 oz - High Tensile Strength Fiberglass Netting Fabric with Silicone Adhesive for Plastering and Jointing.

article:Fiberglass mesh tape has become extremely popular in the construction industry owing its superior strength and durability. The tape is used for drywall finishing, plasterboard joining, and crack repair. One of the top brands in the market is the 99 99 Sheetrock Fiberglass Tape which has a unique cross-fiber construction that provides greater drywall joint strength compared to conventional fiberglass mesh tapes.The 99 99 Sheetrock Fiberglass Tape is made from high-quality materials that make it extremely strong and durable. This tape features a unique cross-fibre construction that provides greater strength compared to other fibreglass mesh tapes. The construction ensures that the drywall joint can bear the weight of external forces and prevents it from cracking or breaking. As a result, users can expect a long-lasting finish that can successfully withstand wear and tear.The self-adhesive feature of the 99 99 Sheetrock Fiberglass Tape is one of its most impressive features. This property makes it extremely easy for users to apply the tape to the drywall surface area. The adhesive gives the tape an excellent grip on the surface, ensuring that it does not peel off. Users can apply the tape to the surface with minimal effort.Furthermore, the tape features excellent alkali resistance. Alkali attack is one of the primary causes of drywall damage and can significantly reduce the lifespan of the drywall joint. The 99 99 Sheetrock Fiberglass Tape is specially designed to resist alkali attack, making it an ideal solution for areas that are prone to these types of damages.Apart from its excellent alkali resistance, the tape also has a high tensile strength. Its strong construction ensures that it can bear heavy loads, making it an excellent choice for construction projects that require a sturdy finish. The 99 99 Sheetrock Fiberglass Tape can also handle cracking and can be used on surfaces that are prone to these types of damages.Another excellent product available from the same brand is the 36-inch Self-adhesive Cement Board Tape. This tape is specially designed for cement board finishing. It is made from durable, high-quality materials that provide an excellent finish to the cement board surface. The self-adhesive property makes it easy to apply, and its excellent grip ensures that it stays in place.The Fiber Mesh Tape is another fantastic product made from woven fiberglass mesh and coated with acrylic acid copolymer liquid. This tape is available in different widths and lengths, making it easy to use for different applications. The tape is an excellent solution for plastering and jointing, and it complements the other products from the same brand.In conclusion, 99 99 Sheetrock Fiberglass tape is a premium product that has gained popularity in the construction industry due to its unique features such as alkali resistance, strength, and self-adhesive property, among others. It is easy to use and provides a long-lasting finish that can withstand wear and tear. Additionally, the brand has other high-quality products such as Self-adhesive Cement Board Tape and Fiber Mesh Tape, which are excellent solutions for different applications. Buyers should consider these products when they need high-quality finishing materials for their construction projects.

Top Self-Adhesive Fiberglass Factories: Product Highlights and Market Trends

Self Adhesive Fiberglass Factories: Bringing Innovative Solutions to the Construction IndustrySelf Adhesive Fiberglass Factories (SAFF) has been widely acknowledged in the construction industry for its innovative self-adhesive fiberglass mesh solutions. The company has been revolutionizing construction practices for more than a decade now with its innovative products and customer-centric approach.SAFF was founded in 2008 with the goal of providing durable and sustainable construction solutions for the modern world. The company’s team of experts has been constantly researching and implementing new technologies to enhance the performance and durability of its products.The self-adhesive fiberglass mesh offered by SAFF is a cost-effective solution that has gained popularity amongst builders and contractors. The product is easy to install, provides additional strength to the structure, and is resistant to cracks and water damage. It is also eco-friendly, as it is made from recycled materials and reduces the need for heavy-duty machinery during installation.SAFF takes pride in its commitment to sustainability, and the company’s production processes are designed to minimize its carbon footprint. It invests heavily in research and development of products that have a low environmental impact and meet the highest quality standards.SAFF’s products are used in multiple applications, such as stucco, plastering, drywall, and EIFS (Exterior Insulation Finishing System). It has a wide range of products in its lineup, including self-adhesive fiberglass mesh tape, corner beads, joint tapes, and high-performance drywall tapes.One of SAFF’s most popular products is its self-adhesive fiberglass mesh tape, which has been extensively used in construct-ion projects worldwide. The product is made from high-quality fiberglass mesh, which is embedded in a layer of adhesive. This provides an excellent bonding between the drywall joints, resulting in a strong and durable structure.SAFF’s corner beads are another innovative product that has gained immense popularity in the construction industry. These corner beads are made from high-strength fiberglass mesh embedded in a layer of adhesive, which provides excellent adhesion and strength to the corners of the structure. These are easy to apply and are resistant to cracks, making them an ideal choice for high-traffic areas.Moreover, SAFF’s joint tapes are ideal for covering the drywall joints, giving a smooth and seamless finish to the wall. The product is made from high-quality fiberglass mesh embedded in a layer of adhesive, which ensures that the joint is strong and durable.SAFF’s commitment to delivering superior-quality products has helped it establish itself as a leader in the construction industry. The company has been expanding its reach to new markets, and its products are now available in more than 20 countries worldwide. The company’s products have been used in some of the world’s most iconic construction projects, including the Burj Khalifa, Dubai, and the Shanghai Tower.In conclusion, SAFF’s innovative products have been providing sustainable and cost-effective solutions to the construction industry. The self-adhesive fiberglass mesh solutions offered by the company have gained immense popularity amongst builders and contractors worldwide. SAFF’s commitment to sustainability, quality, and innovation has helped it establish itself as a leader in the industry. With a wide range of products and a customer-centric approach, SAFF is poised for continued growth in the years to come.

Discover the Benefits of Using 160g Fiberglass Mesh in Your Projects

In recent years, the construction industry has seen an increasing demand for high-quality materials to ensure the durability and longevity of buildings and structures. One of the most crucial components in any construction project is the reinforcement materials used to provide strength and stability to walls, floors, and ceilings. That's where the 160g Fiberglass Mesh comes in.Fiberglass Mesh is a type of composite material that consists of glass fibers woven into a mesh structure. This material is incredibly strong and flexible, which makes it perfect for reinforcing building materials such as concrete and plaster. Fiberglass Mesh is also highly resistant to corrosion, fire, and moisture, making it a popular choice for construction projects in harsh environments.One brand that has been a popular choice among contractors is the 160g Fiberglass Mesh. This mesh comes in rolls of varying lengths and widths, and it is designed to be easy to install and cut to size. The 160g weight of this mesh offers a balance of strength, flexibility, and ease of use, making it an excellent choice for a wide range of applications.The 160g Fiberglass Mesh has been used in countless construction projects over the years, including the construction of residential and commercial buildings, bridges, and tunnels. One advantage of using this type of mesh is that it helps to distribute the load across the entire surface of the structure, reducing the risk of cracks or other damage over time.One of the companies that have been at the forefront of manufacturing and supplying high-quality fiberglass mesh is {This section needs specific company information}. They have been in business for several years and have built a reputation for delivering reliable and durable construction materials. Their 160g Fiberglass Mesh is no exception- it is made from high-quality materials and has been rigorously tested to ensure its strength and durability.One of the key features of this company's 160g Fiberglass Mesh is its ease of use. Unlike some other mesh products that can be challenging to cut or install, this mesh can be easily cut to size with a simple pair of scissors and can be attached to surfaces with any type of adhesive. It is also lightweight, making it easy to handle and transport to various job sites.Another advantage of choosing this company's 160g Fiberglass Mesh is their commitment to quality. They use only the best materials and manufacturing processes to ensure that their products meet the highest standards. They also offer excellent customer service, with knowledgeable staff available to answer any questions or concerns about their products.One of the key benefits of using fiberglass mesh in construction projects is that it can help to prevent cracks and other types of damage from occurring. When applied correctly, the mesh helps to distribute the load evenly across the surface area, thus preventing stress points from forming. This means that buildings and other structures will be less likely to experience damage over time, resulting in lower maintenance costs and longer lifespans.In conclusion, the 160g Fiberglass Mesh is an excellent choice for contractors looking for a reliable and durable reinforcement material for their construction projects. Whether it's used in residential or commercial buildings, bridges, or tunnels, this mesh provides strength, flexibility, and ease of use, making it a popular choice among contractors worldwide. When combined with the quality and commitment of {Company Name}, customers can rest assured that they are getting a top-of-the-line product that will stand the test of time.

Fiberglass Mat Manufacturer Set to Open New Sea Glass Production Plant" Rewritten without brand name: "New Production Plant for Sea Glass Fiberglass Mat Set to Open

Sea Glass, a leading fiberglass mat manufacturer with a longstanding reputation for quality and innovation, is excited to announce the opening of its newest factory. Boasting state-of-the-art equipment and advanced technology, the factory will enable Sea Glass to meet increasing demand for its products and expand its distribution worldwide. Established in 1995, Sea Glass has become a fixture in the fiberglass industry, earning a reputation among its customers for quality, reliability, and exceptional customer service. Its products are used in a wide range of industries, including construction, automotive, marine, and aerospace, among others. With a commitment to using only the highest quality materials and the latest production techniques, Sea Glass has positioned itself as a leader in the industry, consistently delivering products that meet or exceed customer expectations. The new factory, located in a strategic location to serve key markets, is designed to allow Sea Glass to continue to innovate and grow its operations while maintaining its commitment to quality and sustainability. The factory boasts a wide range of cutting-edge equipment that will enable it to produce fiberglass mats of varying thicknesses, densities, and lengths to meet the specific needs of customers in various industries. In keeping with Sea Glass's commitment to sustainability, the factory has been optimized to reduce the company's environmental impact. It features energy-efficient windows and LED lighting, while production processes have been streamlined to minimize waste and maximize efficiency. Additionally, a comprehensive recycling program ensures that any materials that are not used in production are disposed of responsibly. The new factory will provide a welcome boost to the local economy, creating jobs and bringing new opportunities to the region. It is expected to employ around 200 workers and will contribute significantly to the local tax base. But the benefits of the factory extend far beyond the local community. With its expanded production capacity, Sea Glass will be able to meet increasing demand for its products from customers around the world, helping to drive economic growth and support job creation in communities near and far. "As a company committed to continuous improvement and growth, we are thrilled to announce the opening of our new factory," said the Sea Glass spokesperson. "With this new facility, we'll be able to serve our customers even better and meet their evolving needs. We are proud of our reputation for quality and innovation, and we're confident that this new factory will allow us to build on that legacy for years to come." Sea Glass's new factory represents a major investment in the future of the fiberglass industry, in the local community, and in the global economy. Its cutting-edge technology and commitment to sustainability are a model for other manufacturers looking to minimize their environmental impact while meeting the growing demand for high-quality, reliable products. We look forward to seeing all that Sea Glass will achieve with this new facility.

Fiberglass mesh is a common material used in construction and home repairs as it offers strength and durability. Among the different types of fiberglass mesh available in the market, alkali-resistant fiberglass mesh, fiberglass reinforced mesh, EIFS reinforced mesh, glass fiber mesh fabric, drywall tape, and fiberglass screen mesh are some of the most popular options.Alkali-resistant fiberglass mesh, as its name suggests, is designed to resist alkali substances such as cement. It is commonly used in wall and ceiling repairs, especially in wet areas like bathrooms. The woven structure of the mesh provides extra strength to the surface it is applied on, preventing crack formation and improving overall stability.Fiberglass reinforced mesh is another type of fiberglass mesh used to reinforce plaster and other construction materials. Its structure allows for added support to the surface, ensuring that the material remains intact and does not crack easily. It is commonly used in the construction of buildings, bridges, roads, and other infrastructure.EIFS reinforced mesh, on the other hand, is specifically designed for use in exterior insulation and finishing systems (EIFS). Also known as synthetic stucco, EIFS is a popular exterior finish that requires proper reinforcement to maintain its durability. The reinforced mesh helps to keep the EIFS system in place, avoiding cracks and other forms of damage caused by weather and other external factors.Glass fiber mesh fabric is lightweight and easy to install, making it a popular option for many DIY projects. It is commonly used in the construction of concrete countertops, fireplaces, and other home decor items. Glass fiber mesh fabric is resistant to water and chemicals, ensuring that it maintains its strength and durability over time.Drywall tape is another common application of fiberglass mesh in home repairs. It helps to reinforce drywall joints, providing extra support to prevent cracks and other damage. It is commonly used in low-stress areas of the home, such as the ceiling or walls in non-wet areas.Fiberglass screen mesh, on the other hand, is commonly used for window and door screens. The mesh is designed to be durable and withstand the elements, providing added protection to the home while also allowing for fresh air flow.Overall, fiberglass mesh is a versatile and cost-effective material that is useful in a wide range of home repairs and construction projects. Whether you need to reinforce walls, repair drywall, or construct new infrastructure, fiberglass mesh is a reliable and durable choice. As an Alkali Resistant Glass Fiber Tape Manufacturer, we offer high-quality products that meet the needs of different construction and DIY projects. Contact us to learn more about our range of products and how we can help with your next project.

Wholesale Fiberglass Drywall Joint Mesh Tape Supplier for Morocco

China Gold Supplier for Fiberglass Drywall Joint Mesh Tape Wholesale to MoroccoMorocco, situated in North Africa, is a country known for its unique culture, beautiful architecture, and rich history. It is also a nation that values quality and durability when it comes to construction materials. As a result, it's no surprise that Moroccan builders and contractors rely on high-quality, sturdy materials like fiberglass drywall joint mesh tape. China QuanJiang, a leading manufacturer of fiberglass drywall joint mesh tape, recently became a gold supplier for this essential construction material in Morocco. With a wide range of customized self-adhesive fiberglass mesh tape available, China QuanJiang is poised to fill the growing demand for this product across the African continent. Fiberglass drywall joint mesh tape is made from woven fiberglass mesh that's coated with an adhesive material on one side. This adhesive side is then applied directly to drywall seams or joints to reinforce them. The tape creates a stronger bond between the drywall and joint compound, preventing cracks and separation. Fiberglass drywall joint mesh tape is particularly well-suited to the Moroccan climate, as it has excellent resistance to moisture and humidity. This means it can maintain its integrity even in damp environments, such as bathrooms and kitchens. The tape is also highly resistant to wear and tear, making it ideal for use in high-traffic areas like hallways and entryways. China QuanJiang is a highly-respected manufacturer of fiberglass drywall joint mesh tape, with a reputation for producing products that are durable, reliable, and easy to work with. Their tapes are made from high-quality materials and adhere strongly to surfaces, ensuring stable joints that will last for years. In addition, China QuanJiang offers a wide range of customization options for their fiberglass drywall joint mesh tape. Customers can choose from different thicknesses, widths, and lengths to suit their specific needs. They can also select from a variety of adhesive levels and colors to match the color of their drywall joint compound. Customers can get free samples of China QuanJiang's self-adhesive fiberglass mesh tape by contacting the company directly through their website. This allows contractors and builders to test the product before making a purchase, ensuring that they're getting exactly what they need for their specific project. China QuanJiang's commitment to customer satisfaction doesn't end there. They also offer excellent customer service and fast shipping, with orders typically shipped within 24 hours of purchase. This ensures that customers can get their products quickly and efficiently, saving time and money on their construction projects. In conclusion, China QuanJiang is a reliable supplier of fiberglass drywall joint mesh tape, with a wide range of customizable options and a reputation for quality. Their recent gold supplier designation in Morocco demonstrates their commitment to expanding their reach across the international market. Moroccan contractors and builders can trust China QuanJiang to provide them with the high-quality materials they need to build strong, durable, and long-lasting structures.

Discover the Benefits of Glass Fibre Reinforcement Mesh for Construction

Title: Leading Supplier of Glass Fibre Reinforcement Mesh Innovates Construction IndustryIntroduction:In an era where construction practices are undergoing constant advancements, the demand for high-quality and innovative construction materials continues to rise. One such company leading the way is a prominent supplier of glass fibre reinforcement mesh (name omitted). With their cutting-edge product lineup and unwavering commitment to customer satisfaction, they have become a notable player within the industry. In this news article, we will explore the various contributions and achievements of the leading glass fibre reinforcement mesh supplier, highlighting their dedication to revolutionizing the construction sector.Unparalleled Product Range:The glass fibre reinforcement mesh supplied by (company name omitted) is known for its exceptional quality and durability, making it one of the most sought-after materials in the construction industry. Manufactured using state-of-the-art technology and cutting-edge production techniques, these meshes provide superior strength and resistance compared to traditional reinforcement materials. The company boasts an extensive product portfolio, catering to a wide range of construction applications, including wall reinforcement, concrete repair, waterproofing, and flooring systems, among others.Innovation at its Core:At the forefront of their success lies (company name omitted)'s emphasis on innovation. With a dedicated research and development team, they continually strive to engineer products that meet evolving industry demands. By leveraging advanced manufacturing processes and incorporating modern material science, the company consistently introduces groundbreaking solutions that enhance the durability and stability of construction projects.Collaborative Approach to Customer Satisfaction:From small-scale residential projects to large-scale commercial ventures, (company name omitted) understands the importance of tailored solutions. They work closely with their clients, offering expert guidance and support to meet the specific requirements of each project. Their team of experienced professionals ensures a seamless integration of their glass fibre reinforcement mesh into diverse construction environments, assuring high efficiency and longevity.Focus on Sustainability:In addition to their commitment to product innovation, (company name omitted) places great importance on sustainability. Recognizing the environmental impact of the construction industry, they aim to reduce their carbon footprint through responsible manufacturing practices. The raw materials used in the production of their glass fibre reinforcement mesh emphasize recyclability and eco-friendliness, aligning with global sustainability goals.Expanding Global Footprint:Through their relentless pursuit of excellence, (company name omitted) has successfully established a strong global presence. By forging strategic partnerships with renowned distributors and construction companies worldwide, the company has been able to reach diverse markets and serve an extensive customer base. Their commitment to quality and reliability has earned them a stellar reputation, cementing their position as a preferred supplier of glass fibre reinforcement mesh internationally.Investing in Advanced Technology:To stay ahead in the rapidly evolving construction industry, (company name omitted) demonstrates a continued focus on cutting-edge technology. By investing in state-of-the-art machinery and equipment, they ensure maximum efficiency throughout the production process. With the integration of automation and quality control systems, they guarantee consistent product performance and uphold stringent industry standards. This dedication to technological advancement enables them to not only meet but exceed customer expectations consistently.Conclusion:In a thriving construction industry, the need for innovative materials cannot be overstated. As a leading supplier of glass fibre reinforcement mesh, (company name omitted) has played a pivotal role in transforming construction practices worldwide. Their commitment to quality, sustainability, and customer satisfaction has earned them a prominent position within the industry. With a relentless focus on innovation and advanced manufacturing techniques, they continue to provide construction professionals with reliable solutions to enhance project efficiency and longevity. As they forge ahead, (company name omitted) is poised to revolutionize the construction sector further.

Top Alkali Resistant Fiberglass Manufacturers: Key Players in the Industry

Alkali Resistant Fiberglass Manufacturers Launches Latest Line of ProductsAlkali Resistant Fiberglass Manufacturers, one of the leading companies in the field of fiberglass, has recently launched its latest line of alkali-resistant fiberglass products. The company has been supplying premium quality fiberglass products for over a decade, catering to a wide range of industrial applications.The new line of products features a unique composition that makes it highly resistant to alkali, a property that is vital in applications where the material is exposed to alkaline substances. The products are known for their high strength, durability and resistance to corrosion, which makes them ideal for use in various environments.Alkali Resistant Fiberglass Manufacturers is an industry leader in the field of fiberglass production, and has an excellent reputation for providing high-quality products to its clients. The company has invested heavily in research and development, which has led to the creation of new and innovative products that have set new standards in the industry.Apart from manufacturing alkali-resistant fiberglass products, the company also produces a wide range of other fiberglass products that cater to various industrial applications. This includes fiberglass pipes, tanks, panels, grating, among many others. The products are designed to meet industry standards and are rigorously tested to ensure their durability and strength.With their latest line of products, Alkali Resistant Fiberglass Manufacturers aims to further expand its market reach and provide high-quality products to a wider range of industries. The company has always emphasized customer satisfaction and after-sales service, which has enabled it to build long-term relationships with its clients.Alkali Resistant Fiberglass Manufacturers has a state-of-the-art production facility that boasts of the latest technology and machinery. The company has a team of highly skilled professionals who are trained to ensure that the products are manufactured in compliance with the highest standards of quality and safety.Speaking about the new line of products, the spokesperson of the company said, “We are delighted to launch our latest line of alkali-resistant fiberglass products. Our products have always been known for their durability and strength, and the new line is no exception. We are confident that these products will cater to the needs of our customers and enable us to expand our market reach further.”The company’s commitment to sustainability and maintaining a green environment also sets it apart from its competitors. Alkali Resistant Fiberglass Manufacturers uses eco-friendly materials and processes while manufacturing their products, thereby reducing their carbon footprint and contributing to environmental protection.The company’s vision is to become the industry leader in the field of fiberglass production and establish a global presence. It aims to achieve this by investing in research and development, continuously improving its products and expanding its reach into new markets.With its latest line of products, Alkali Resistant Fiberglass Manufacturers is all set to establish itself as a leader in the production of alkali-resistant fiberglass products. The company’s commitment to quality and customer satisfaction, combined with its focus on environmental sustainability, sets it apart from its competitors and ensures its continued success in the industry.